HOW DOES SIGSENSE HELP?

Increased VISIBILITY and INSIGHT.

By directly monitoring your testing equipment, Sigsense delivers operational insights you don’t have now, to drive a level of performance you didn’t know was possible.

By directly monitoring your testing equipment, Sigsense delivers operational insights you don’t have now, to drive a level of performance you didn’t know was possible.

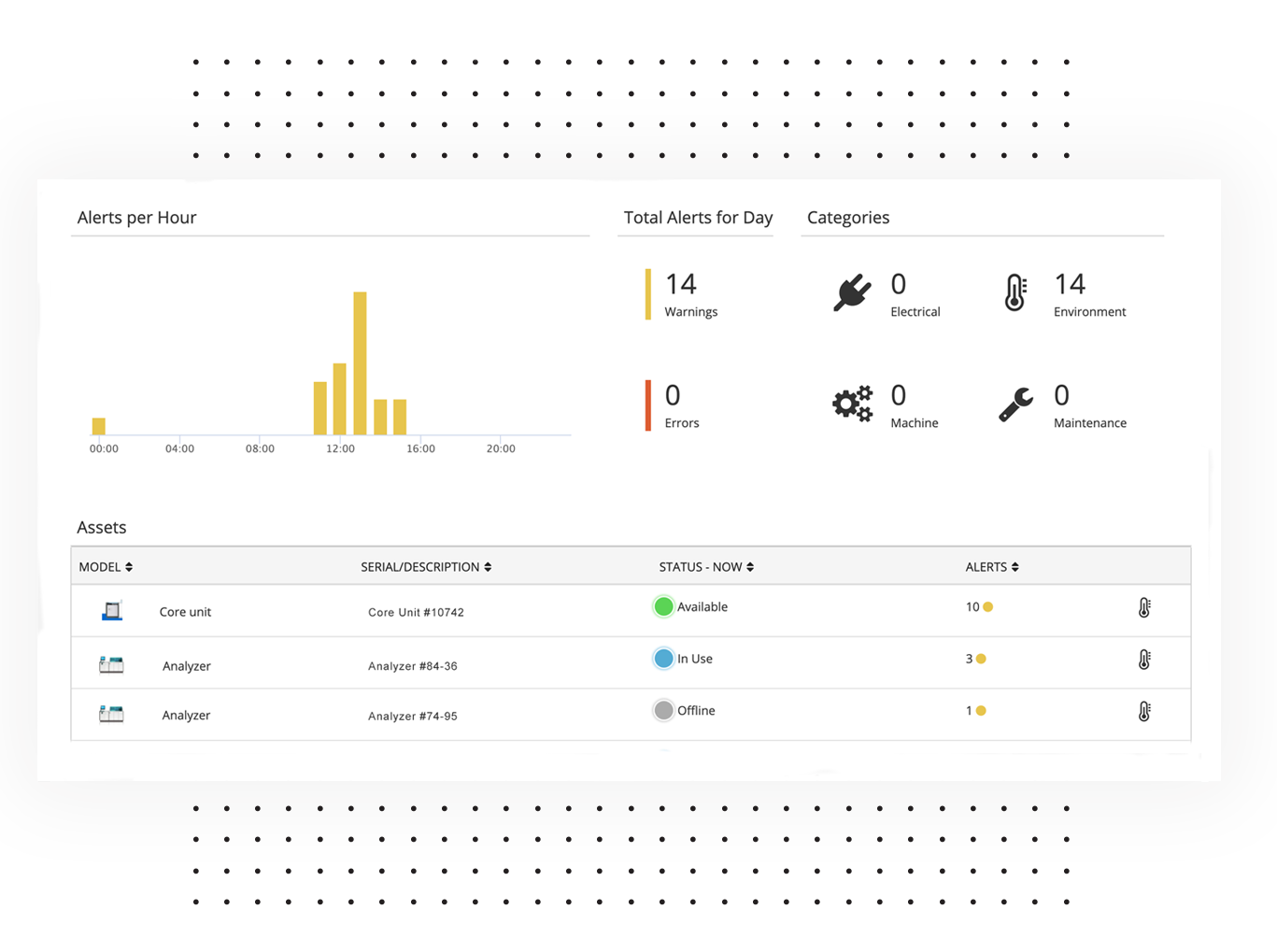

Facility-level insights into capacity, throughput, and downtime.

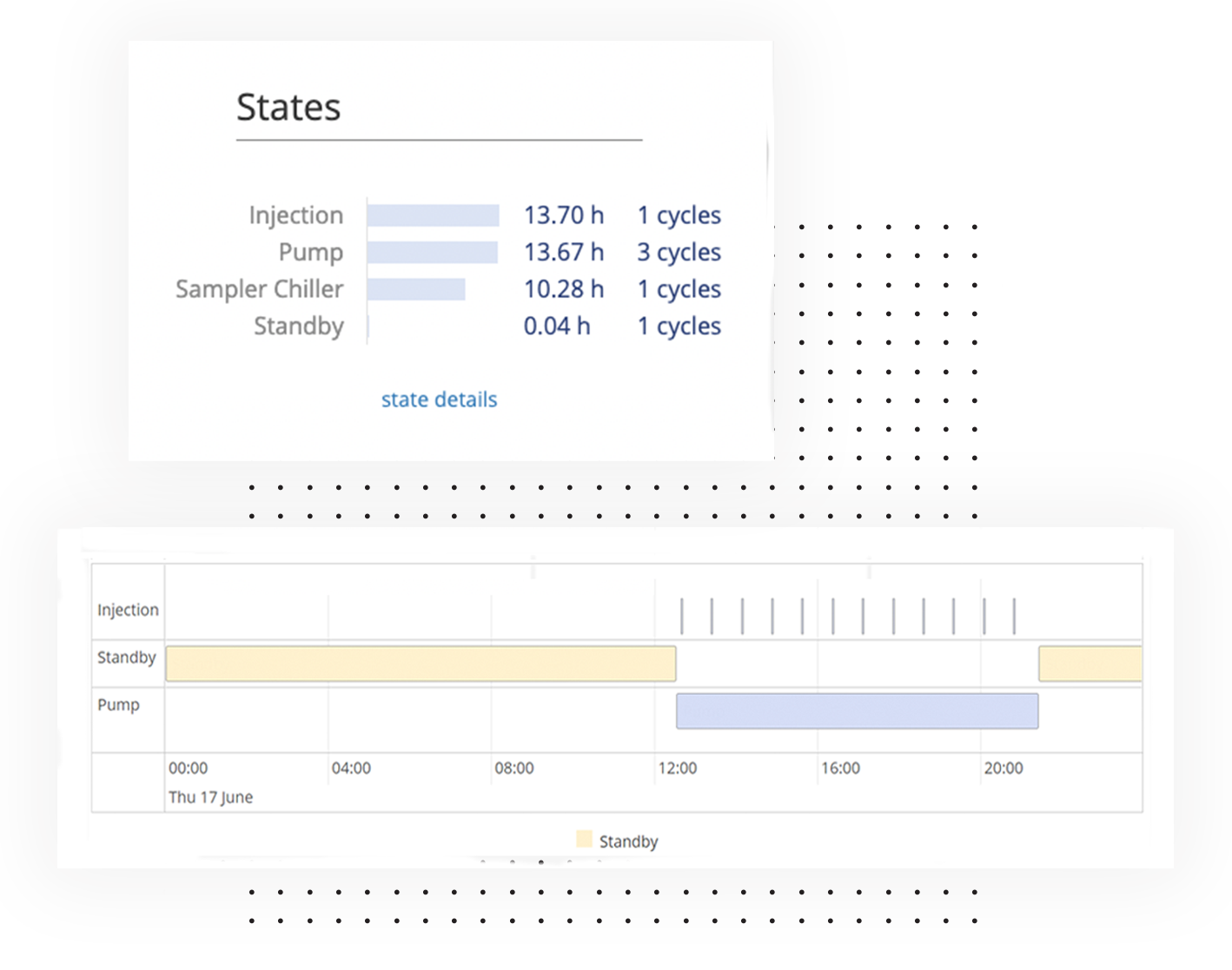

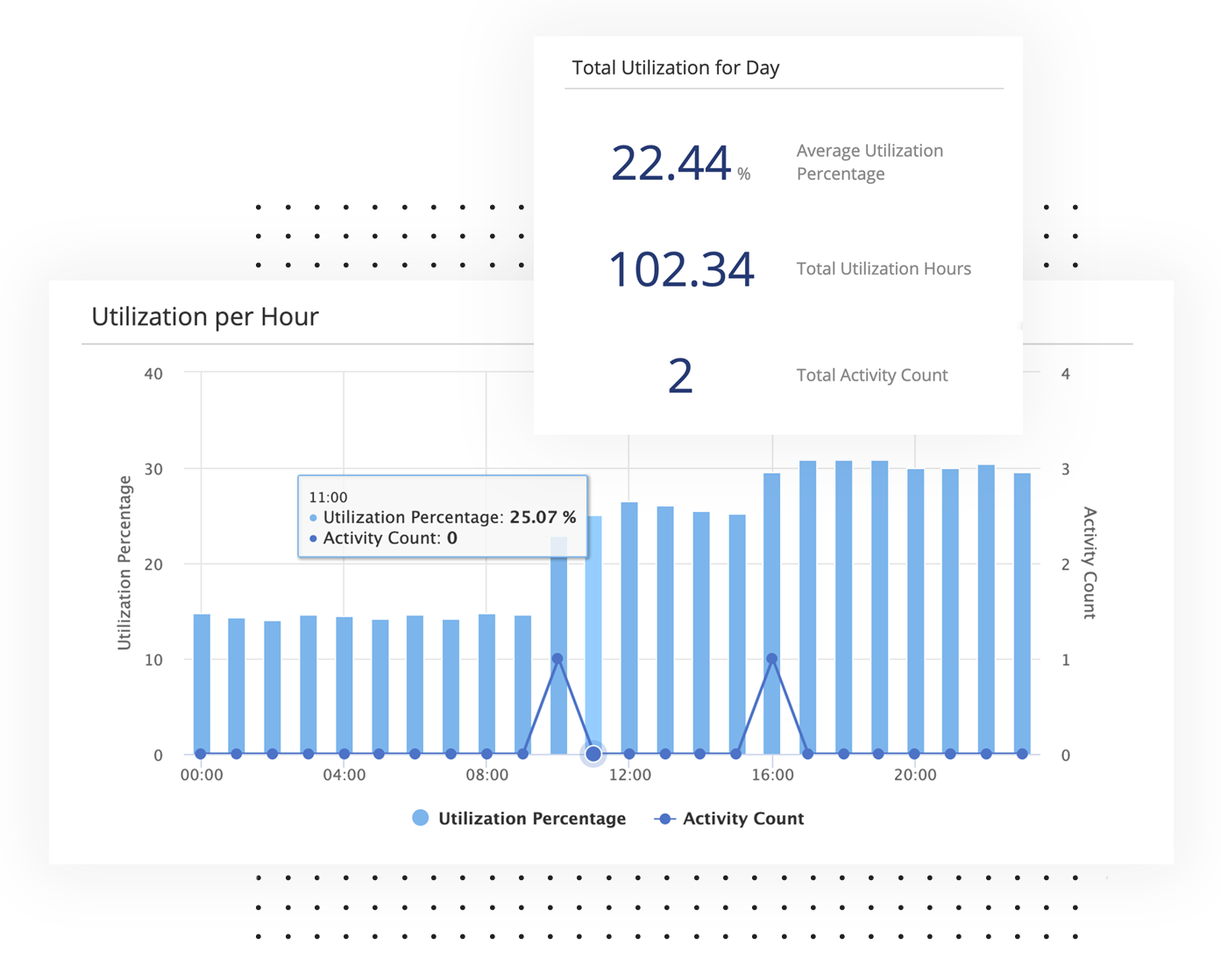

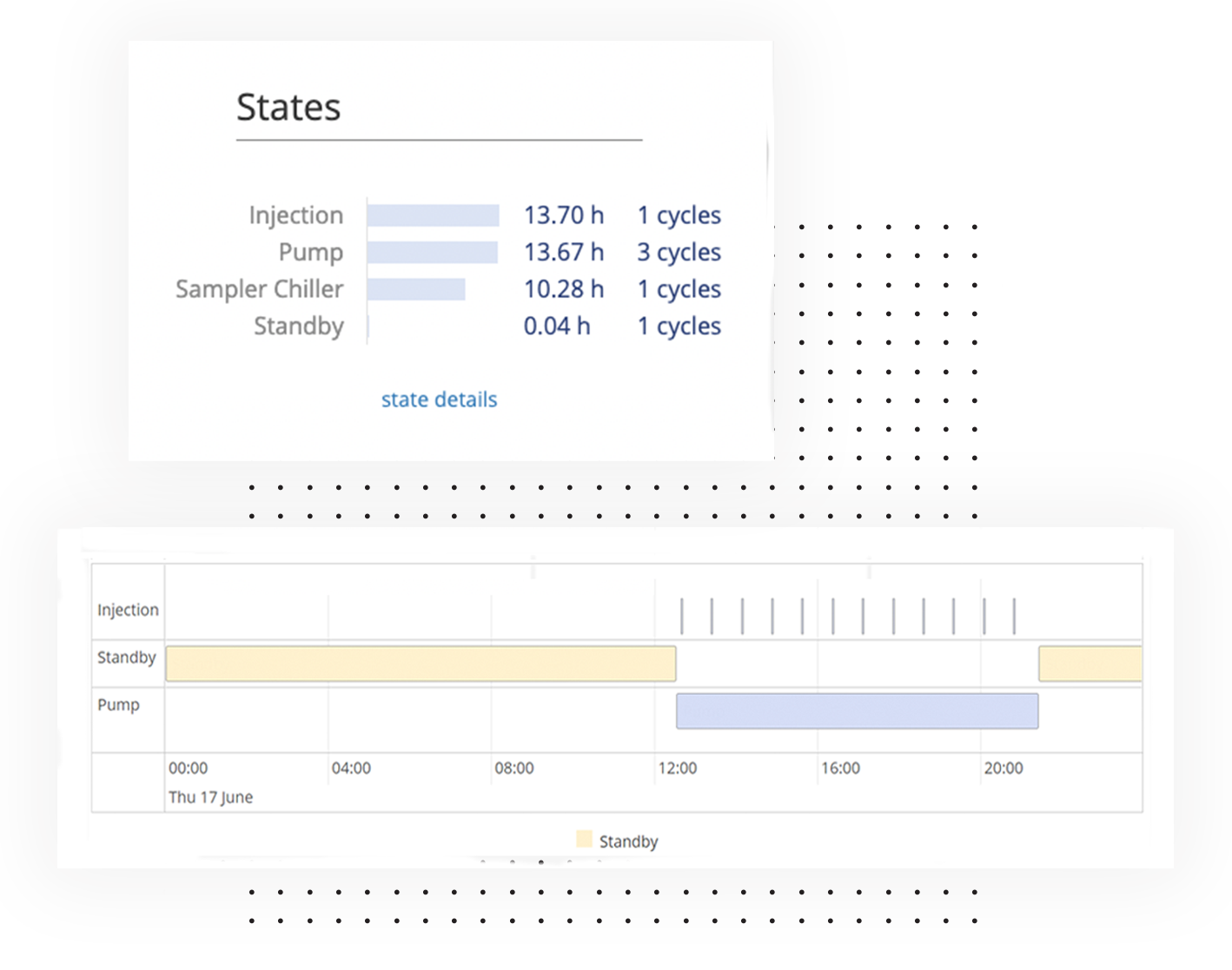

Detailed, time-stamped accounting of equipment usage, reporting of what causes disruptions, and algorithmically tracked OEE metrics.

Make sure your capital spend directly matches your organizational needs.

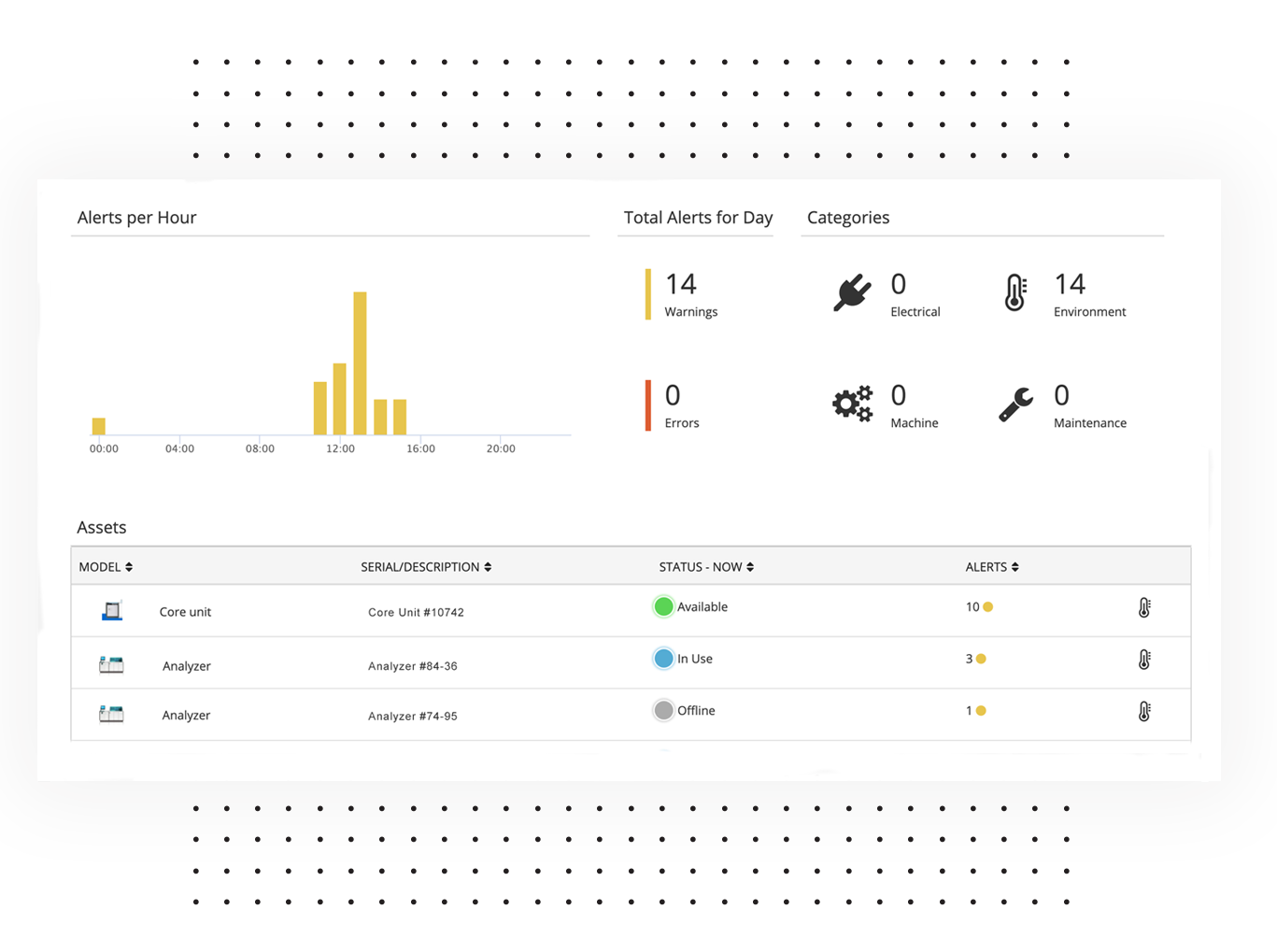

Track slowdowns, stoppages, and errors. Quickly get insights for corrective action.

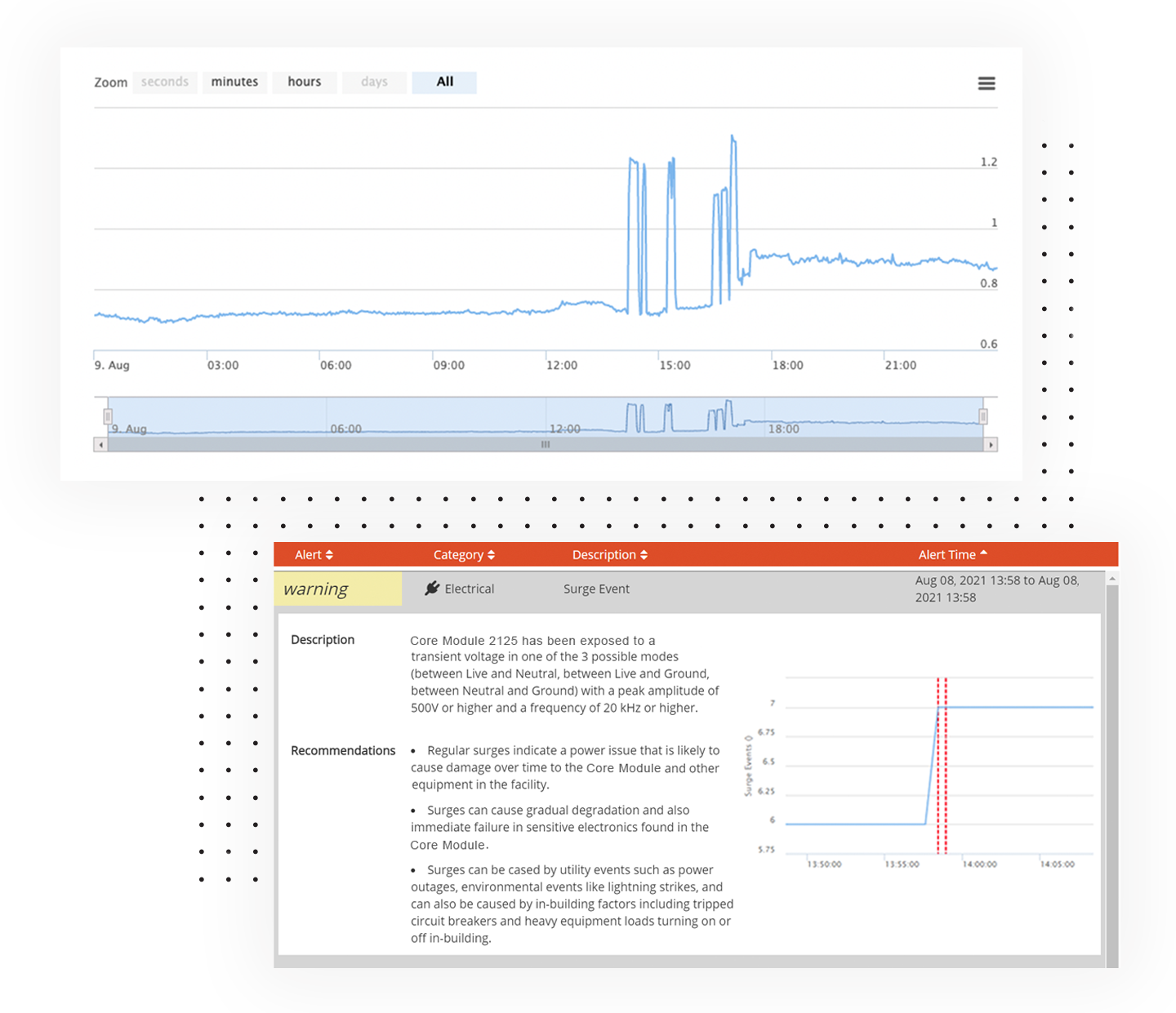

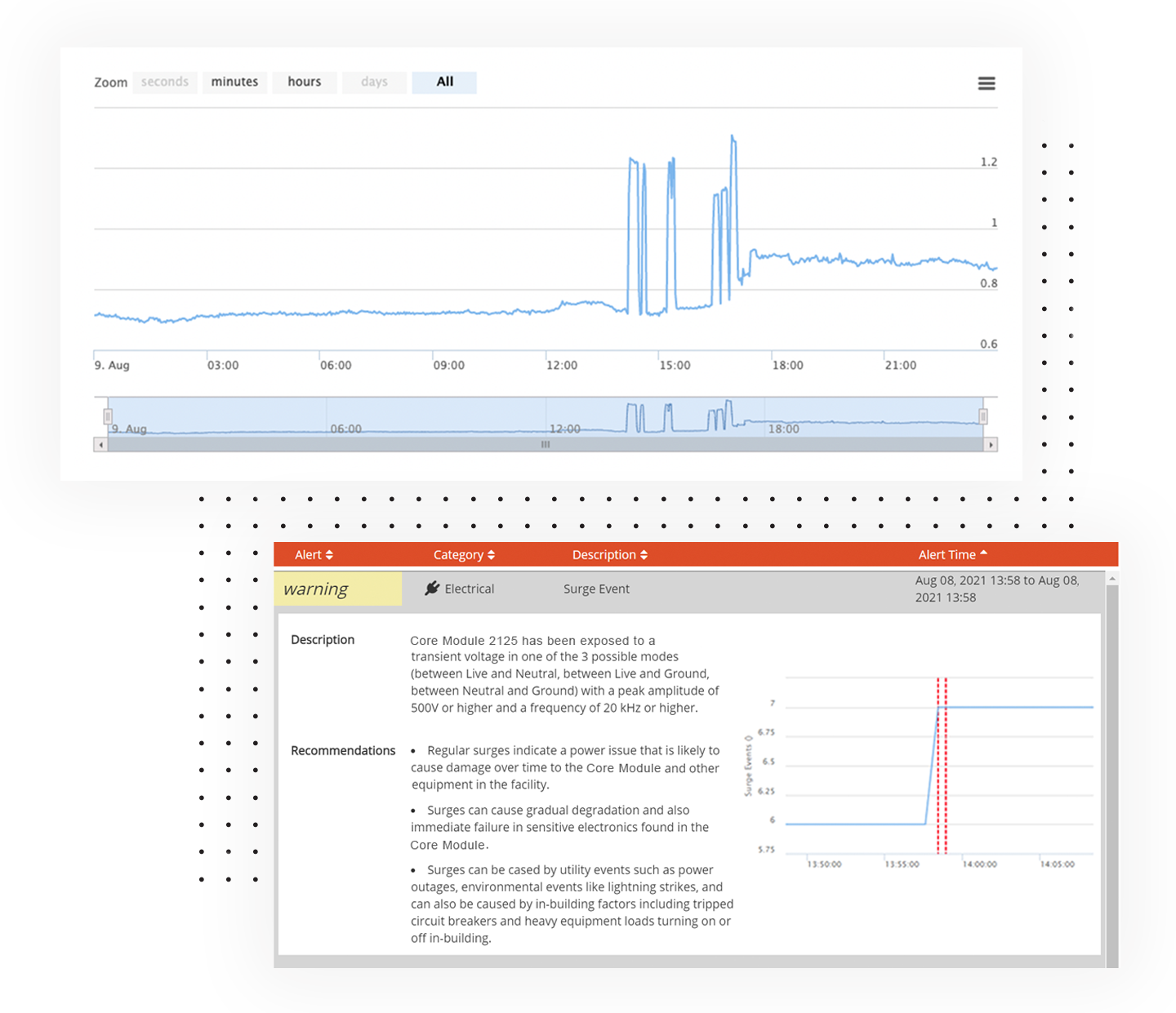

Track equipment condition and, when issues are detected, deliver immediate notifications to preempt equipment failure and operational disruptions.

Facility-level insights into capacity, throughput, and downtime.

Detailed, time-stamped accounting of equipment usage, reporting of what causes disruptions, and algorithmically tracked OEE metrics.

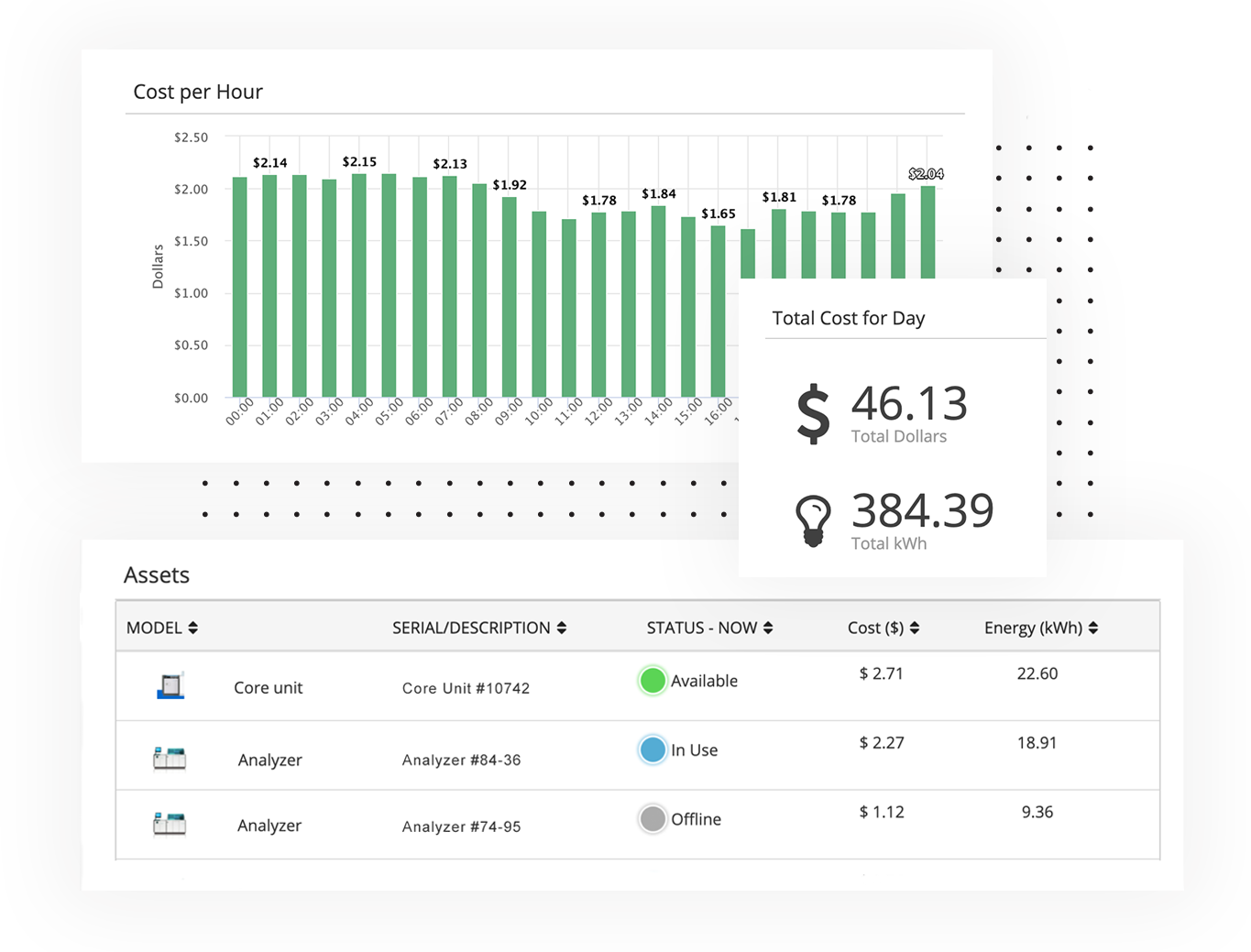

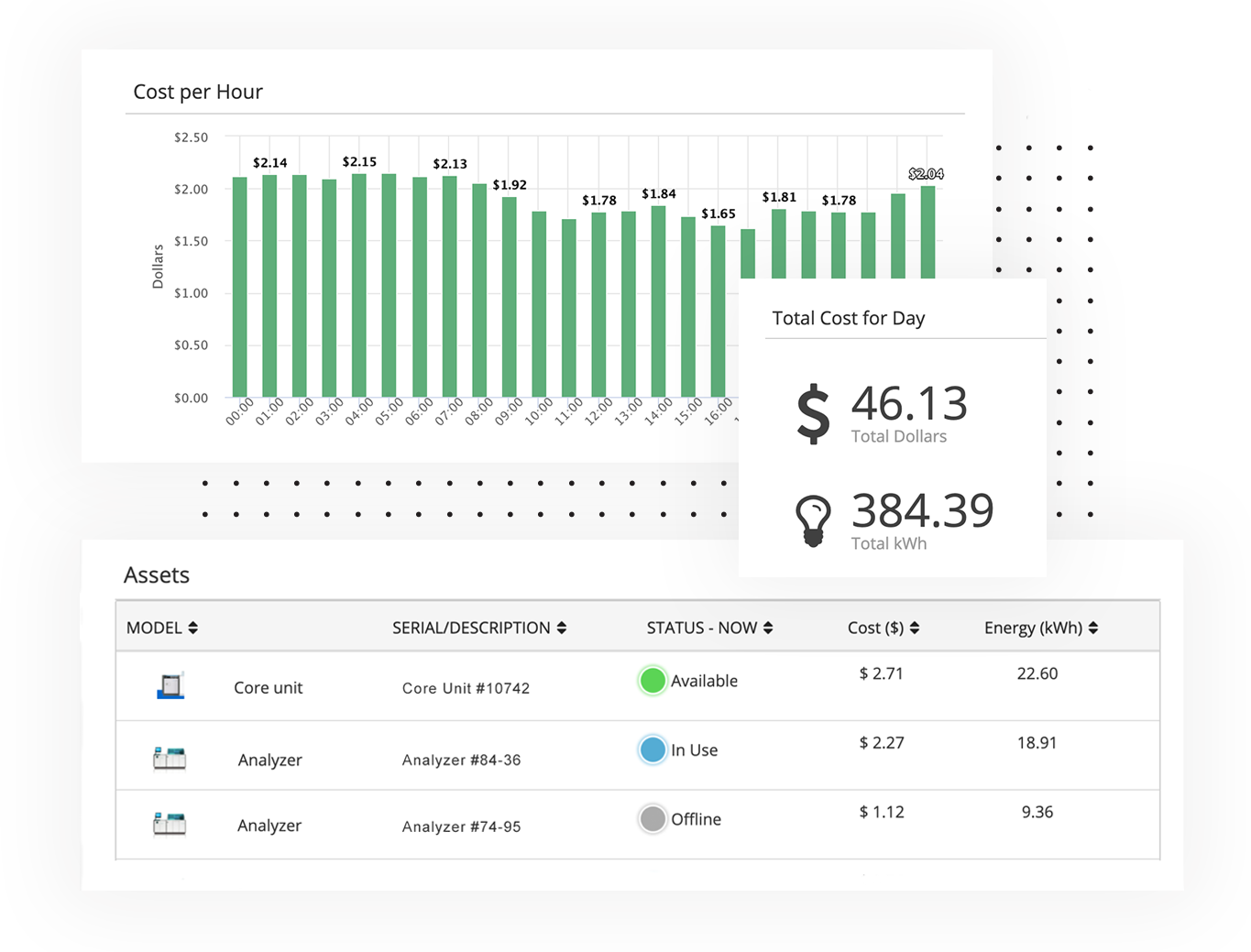

Make sure your capital spend directly matches your organizational needs.

Track slowdowns, stoppages, and errors. Quickly get insights for corrective action.

Track equipment condition to the individual component level and, when issues are detected, deliver immediate notifications to pre-empt equipment failure and operational disruptions.

Sigsense eliminates the guesswork in your operations.

Average throughput increase

Account for your operational inefficiencies. Find and remove stoppages, identify workflow improvement opportunities, and minimize downtime.

Average capital spend reduction

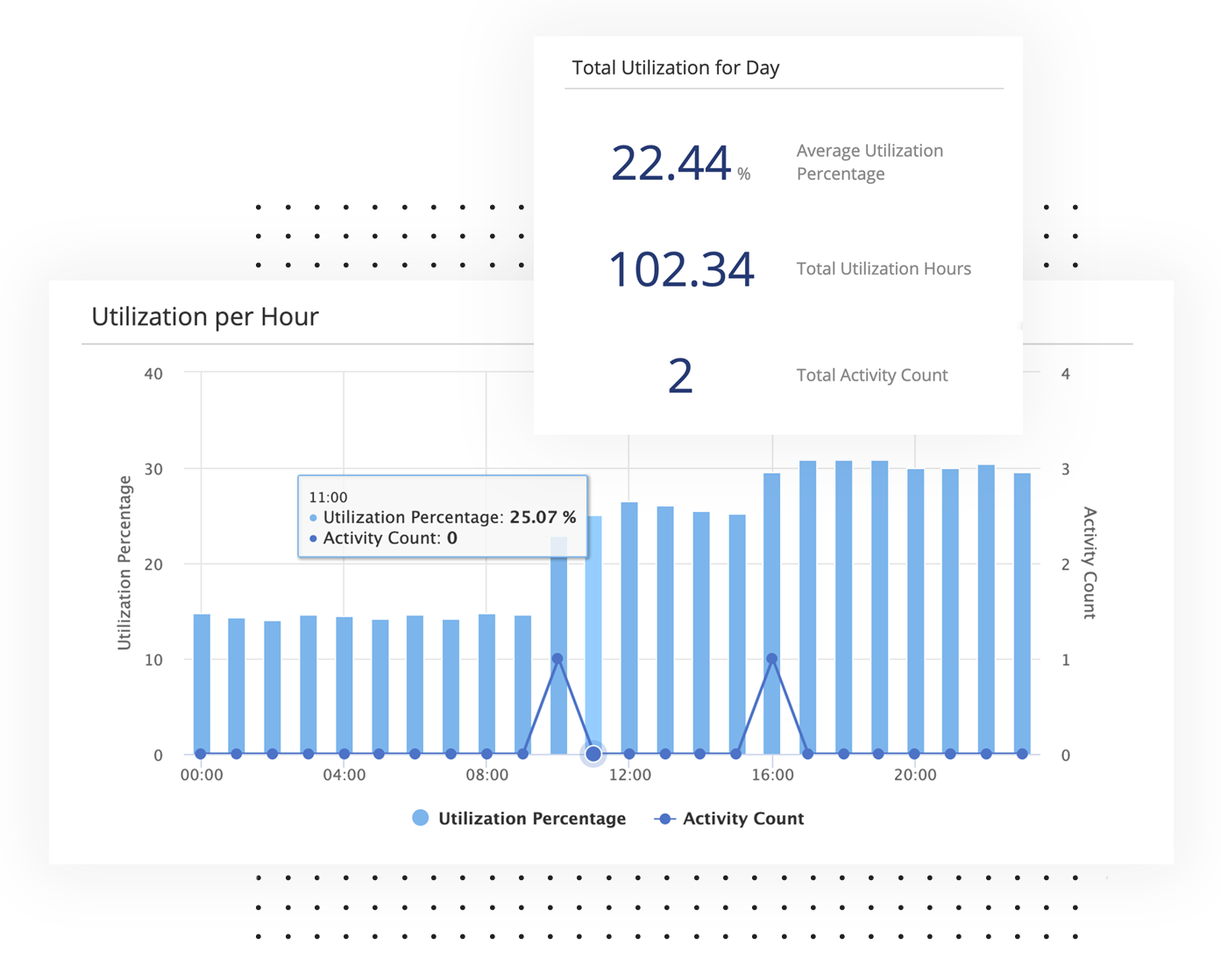

Immediately view equipment usage, availability, and peak hours in real time to track asset productivity, efficiency, and ROI.

Average service & consumable cost decrease

Identify and triage anomalous equipment behavior to predict and prevent a total failure.

Sigsense’s non-invasive power monitors quantify the performance of any equipment that uses electricity, from receiving scales to mass spectrometers.

Our AI aggregates and analyzes equipment behaviors to deliver a complete view of your operations at the asset, group, and facility-wide levels.

The platform identifies anomalies, flags issues in real time, and delivers proactive alerts to both improve operations and prevent disruptions.